#Hand operated batch printing machine

Explore tagged Tumblr posts

Note

Rusty again Okay... so, I'm sharing the fan-child. First I wanna paint the picture behind this fan-child and why I see this toon-ship. (admittedly, might be difficult to really see it with Gavin. But I can still see it because it is... pretty one sided in how I paint it.) You ever read those stories where a werewolf-like monster wants to be stopped but they can't stop themselves? How a self-loathing beast waits for the day the brave hero stops them? Well... I kinda imagine Dandy in that case... He is hiding TONS of stuff from the toons. And we don't know how far his tunnel of secrets reach. We don't know how intentional it was when he caused the ichor operation or if he even caused it, by all accounts he could be framed and trying to pick up the pieces the best he can. So... I decided to put myself into the shoes of Dandy. I twist temporary if they ignore my shop for long enough, I have self control as I don't just twist right away when they hit my limit. I can hold back until I can't. (To explain how he just had a ever increasing likihood of spawning during a dandy run) these are my friends. I sell what I can to help. I wish to speak openly but would they be friends with a monster? Would them trying to help me hurt them? ... Long ramble short. I imagine Dandy in a sort of 'masked-depression'. He puts on a face that all is well, he does his best to stay cheery and do his own thing. But... he isn't well. He blames himself for the twisteds, he blames himself for the shutdown (theory for another time) and he blames himself for BEING a twisted. When we don't even know if he can control it. ... Now that I painted this idea of Dandy... entering center stage is the knight. Suitor. A hero everyone loves, the shining knight of Gardenview. The... okay I struggle to think of more titles but you get the point. I imagine that... at least this image of Dandy... couldn't help but fall a little in love with Suitor as a idea. And seeing him save their friends every run? Seeing him put in the work to keep them safe the best he can? Seeing him be the hero he is? ... well. I can't help but picture little intrusive thinking. Slowly worming its way to the center of his head. Making it hard to think of all the things he has to do. Onto the final act. The child. Now, I'm VERY HAPPY you believe I'm a genius for the idea of my last rambling ask. So... playing onto that... Dandy is just one toon. Who does things by himself because of reasons, who hides stuff he does because of reasons. And even with Astro. Who he still talks to a times. He hides things from his best friend, his first friend. ... So... why not have a little mistake... a little train of thought... he doodles. Doodles, and doodles some more. At first, a way to stave off boredom while waiting for the toons with the machines while he is in the elevator. But it slowly grows until he decides to let the intrusive thoughts win and prints a toon egg. "Briar" the name he paints onto the egg. And... like how he did with the last batch... he delivers it. He doesn't quite place it at Suitors' door but he puts it where he knows suitor, or at least someone would find it. The child won't know him. It may be obvious to those who pay attention but... He needed to do something to get this idea out of his head. Briar post hatching is based off two things. A Venus flytrap and a serpentine-like dragon. A long body of slithering vines, a pair of leaf-like wings, and two front legs/arms. Ending in a pair of bush-like paws/hands. Their head is a simple flytrap, with two roses for eyes. Briar. Personality wise. I'm not sure what to really say here... compassionate yet foolhardy. Bit of a airhead but loyal to a fault. Due to his strength, he adopts... a oversized executioners' sword prop as his 'family weapon'. A giant foam sword for Suitors' floor and medieval event. Used in some kind of foam weapon arena for kids and those who love to larp/hit other people with foam weapons. Sorry for the word wall, gonna hit ask now.

Rusty, how are you cooking SO MUCH, this is amazing, I LOVE it.

Just, one sided Dandy loving and idolizing Suitor while also hating him, he made Briar on a whim, maybe right after twisting and not in his right mind.

To make a proper child toon that's genetically related to two others you need to mix their ichor, Dandy wipes Suitor's off his claws...

Suitor keeps Briar's egg a well hidden secret, he knows what it is, knows it could be dangerous to let hatch, but he is not the kind of person to do that, this child has done nothing wrong except exist, it doesn't deserve that fate simply because of who fathered it...

In the Classic timeline Briar is unaware of their parentage other than Suitor and the Council.

In the Spooky Siblings timeline however, it's much harder to hide... They look much more like Dandicus...

I have some roughs I'm not going to finish any time soon;

"Classic" Briar, Dandy was in a right enough mind to properly mold them into something (a Venus fly trap)

And "SS" Briar... Dandy was quite well out of his mind while making them, making a carbon copy of himself...

Also I keep mentally assigning Briar she/her pronouns in my head even though you refered to them as "him" so... ATAC (Assigned Trans At Concept) /hj

#dandy's world#dandy's world dandy#dandy's world sir suitor#dandy's world original character#dandy's world oc#spooky siblings timeline#not my oc#we keep making more fankids#This one is FUN though#so much potential ANGST#she's just like her dad#which dad?#...#guess ;3

12 notes

·

View notes

Text

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes

Text

How Digital Textile Printing is Revolutionizing the Fabric Industry

The Need for Innovation in Textile Printing

Historically, fabric printing relied on methods like screen printing or rotary printing. These techniques are cost-effective for large runs but are inefficient for small batches or designs requiring intricate detail. Enter the digital textile printing revolution. This method allows for direct-to-fabric printing using inkjet technology, providing limitless design freedom without the setup costs of conventional techniques.

The Role of the Modern Printing Machine

At the heart of this innovation lies the printing machine itself. Today’s advanced machines come equipped with high-resolution nozzles, AI-based controls, and specialized software that ensure sharp, vibrant prints. These machines can handle complex designs, multiple colors, and even print on various types of fabrics—from cotton and silk to synthetic blends.

More importantly, digital textile printers enable on-demand production. This means that designers can now test patterns, release limited collections, or even allow customers to personalize products—without worrying about inventory waste or long lead times.

Delivering on True Colour Accuracy

One of the standout features of digital textile printing is its ability to maintain true colour accuracy across batches. Traditional methods often suffer from color bleeding or tone shifts due to manual ink mixing and inconsistent application. But with digital technology, color management systems ensure consistency and precision.

This fidelity is crucial for fashion brands where brand identity depends heavily on specific color palettes. Interior designers also benefit, as they can now match fabrics precisely to walls, furnishings, or other décor elements.

Sustainability and Efficiency Go Hand-in-Hand

In an era where environmental responsibility matters, digital textile printing scores high on sustainability. It uses less water, reduces chemical waste, and minimizes leftover stock—making it a greener choice for both small and large textile businesses.

Traditional dyeing methods consume vast amounts of water and produce effluents that are difficult to treat. Digital systems, however, print only what is needed, drastically cutting down pollution and energy usage. A modern textile printing machine can now create hundreds of designs per day with minimal environmental impact.

Applications Beyond Fashion

While fashion remains the most visible industry adopting this technology, digital textile printing also plays a pivotal role in sportswear, accessories, interior décor, and even technical textiles. Whether it’s vibrant cushions, printed upholstery, or personalized yoga mats, the possibilities are endless.

For startups and indie brands, this levels the playing field. High-quality, custom products can be created with relatively low capital investment—thanks to compact printing machines suited for studio-scale operations.

Final Thoughts

The rise of digital textile printing marks a shift from mass production to mass customization. With capabilities that ensure true colour, faster turnaround times, and eco-conscious operations, the modern textile printing machine is more than just a tool—it’s a gateway to the future of design and manufacturing. As technology advances further, the textile industry can only expect better precision, scalability, and creative freedom.

0 notes

Text

Discover How 3D Print Services and Cheap 3D Printer India Solutions Are Transforming Innovation

In recent years, 3D printing technology has emerged as a powerful tool across industries—from prototyping and manufacturing to healthcare and education. Businesses and individuals alike are reaping the benefits of rapid, cost-effective production using modern 3D printers. With increasing accessibility, more Indians are turning to 3D print services and exploring options for a cheap 3D printer in India to bring their ideas to life.

Why 3D Printing Is Gaining Momentum

3D printing, also known as additive manufacturing, creates physical objects by layering material based on a digital model. This process dramatically reduces waste, speeds up prototyping, and allows for the customization of products that traditional manufacturing struggles to offer.

Designers, architects, engineers, hobbyists, and students are now using 3D printing for projects ranging from miniatures and machine parts to architectural models and medical implants. The rising interest has spurred the growth of reliable and affordable 3D print services and a market boom for cheap 3D printer India options.

What Are 3D Print Services?

3D print services allow you to print a design without owning a 3D printer yourself. You simply upload your CAD file to an online portal or visit a local 3D printing center, choose your preferred material, and let experts do the rest. These services are ideal for those who need professional prints occasionally or want high-quality output without investing in expensive machines.

In India, the demand for professional 3D printing has surged across metro cities like Bangalore, Delhi, Mumbai, and Hyderabad. Companies offer services like rapid prototyping, industrial modeling, product design, and even small-batch production. Whether you're a student working on a science fair project or a startup developing a new prototype, 3D print services provide flexible, on-demand solutions.

Exploring the Market for a Cheap 3D Printer in India

While outsourcing printing to professional services is convenient, many hobbyists and startups prefer owning a machine for hands-on experience and long-term savings. The good news is that the Indian market offers a wide range of options for those seeking a cheap 3D printer in India without compromising on performance.

Entry-level FDM (Fused Deposition Modeling) printers are now available at affordable prices, starting as low as ₹15,000 to ₹30,000. Brands like Creality, Anycubic, Wanhao, and Indian-made Pramaan 3D have released budget-friendly models that cater to both beginners and advanced users.

These machines support common filament types like PLA, ABS, and PETG, and some even come with open-source firmware for customization. With online tutorials and active user communities, it’s easier than ever to set up and operate a cheap 3D printer in India from your home or workshop.

Benefits of Using 3D Print Services and Owning a Cheap 3D Printer

Both 3D print services and affordable personal printers offer distinct benefits, depending on your needs:

Advantages of 3D Print Services:

Professional Quality: Get access to high-resolution industrial-grade printers.

Variety of Materials: Choose from advanced resins, metals, and composites.

No Maintenance Hassle: Avoid the setup, calibration, and upkeep involved in running your own printer.

Expert Guidance: Collaborate with technicians who can help optimize your design for the best results.

Advantages of Cheap 3D Printers in India:

Affordability: Entry-level printers are budget-friendly and easily available online and offline.

Learning Opportunity: Great for students and makers to understand the nuances of 3D modeling and printing.

Creative Control: Make quick iterations and modifications in real time without relying on a third party.

Business Potential: Entrepreneurs can start small-scale manufacturing or offer local 3D print services in their area.

Who Can Benefit from 3D Printing?

The applications of 3D printing extend far beyond engineering and manufacturing. Here’s a look at some key users:

Students and Educators: Ideal for STEM education, science models, and project-based learning.

Architects: Use 3D printing for scale models, elevation designs, and visual presentations.

Healthcare Professionals: Print prosthetics, surgical tools, and anatomical models.

Artists and Designers: Bring creative ideas to life with customized jewelry, home decor, and wearable tech.

Entrepreneurs: Launch product-based businesses with minimal initial investment using a cheap 3D printer India setup.

Final Thoughts: Embrace the Future with 3D Printing

The 3D printing landscape in India is rapidly evolving. As awareness grows, both 3D print services and affordable home-use machines are making innovation more accessible than ever. Whether you want to prototype a new invention, create personalized items, or enter the world of digital manufacturing, now is the perfect time to explore your options.

Investing in a cheap 3D printer in India or partnering with a local 3D print service can unlock endless possibilities for your creativity or business. As technology continues to advance, those who adopt 3D printing today will lead the way in shaping the products and solutions of tomorrow.

0 notes

Text

Custom Plastic Injection Molding

Custom plastic injection molding is the preferred solution for companies that need specialized plastic parts tailored to exact design specifications. At XCMachining, our custom plastic injection molding capabilities enable clients across diverse industries—such as aerospace, medical, and consumer goods—to achieve parts with specific material properties, complex geometries, and tight tolerances.

Our custom approach begins with in-depth consultations. During this stage, our design engineers work hand-in-hand with clients to review CAD models, suggest design for manufacturability (DFM) improvements, and select suitable thermoplastics—whether you need medical-grade polycarbonate or engineering-grade PEEK. By optimizing gate location, wall thickness, and draft angles, we reduce cycle times and ensure part consistency.

Once the design is finalized, we create precision molds using high-quality tool steel and 5-axis CNC machining. Our mold-making expertise guarantees excellent surface finishes and consistent cavity replication. With multi-cavity and family mold options available, we can seamlessly transition from prototype runs to high-volume production, saving you both time and money.

XCMachining’s custom plastic injection molding offers more than just part fabrication. We deliver end-to-end project management, including mold flow analysis, material selection guidance, and secondary operations such as ultrasonic welding or pad printing. Our in-house quality lab employs color spectrophotometers, tensile testers, and coordinate measuring machines (CMM) to validate that each batch of parts adheres to stringent customer requirements.

Flexibility is a hallmark of our service. Whether you require low-volume runs for market testing or large volumes for full product launches, our scalable production line adapts to your timelines. Lead times are minimized through our efficient scheduling and rapid tool-building capabilities, enabling you to hit market windows faster.

Choosing XCMachining for custom plastic injection molding means entrusting your part development to a team committed to innovation, precision, and customer satisfaction. From initial concept all the way through quality inspection, we ensure your custom plastic parts meet performance expectations and contribute to your product’s success.

0 notes

Text

OPTO 1200 Quick Measuring Machine — Precision Screw Inspection in Just Seconds

Opto1200- Optomech engineers pvt ltd

Revolutionize Your Quality Control with Instant, Accurate, and Hands-Free Measurement

Intoday’s era of micro-precision and mass production, quality inspection is no longer just about checking dimensions — it’s about doing it faster, smarter, and without compromise. Whether you’re manufacturing automotive components, aerospace fasteners, or industrial-grade tools, ensuring that every screw meets exact specifications is non-negotiable.

Enter the OPTO 1200 Quick Measuring Machine — a powerful, camera-based dimensional inspection system that allows users to measure 2D parts like screws instantly with incredible accuracy, without operator intervention. No complex setup. No manual handling. Just place the part, press a button, and let the system do the rest.

Why Choose OPTO 1200 for Screw Inspection?

Screws, though seemingly simple, are geometrically complex. They include multiple critical parameters like:

Thread pitch

Head diameter

Shaft length

Chamfer angle

Root diameter

Any deviation can result in poor fit, torque failure, or total product rejection.

Traditional methods like calipers, micrometers, or profile projectors are time-consuming and subject to human error. With OPTO 1200, you can measure every screw in seconds, store the results, and even generate reports — all with minimal training.

Real-World Application: Measuring a Precision Screw

Let’s walk through how a screw is measured using the OPTO 1200 system:

Step 1: Template Creation

Using Opto Precision V1 software, a template is created by simply drawing around the screw’s edge.

The software auto-detects contours and generates geometric elements like lines, circles, and arcs.

Nominal dimensions and tolerances are input by the quality team.

Step 2: Place and Measure

The operator places the screw on the OPTO 1200 stage.

On clicking the “Measure” button, the system:

Captures the image

Matches it with the template

Automatically measures:

Head diameter

Thread pitch

Shank length

Chamfer angles

Concentricity

Provides instant PASS/FAIL validation

Step 3: Reporting

The results are stored in a secure database.

A statistical report including Min, Max, Mean, Std Dev, CPK is generated.

Reports can be exported or printed as per requirement.

This is true plug-and-play metrology, making it a must-have tool for modern precision workshops.

What Makes OPTO 1200 Unique for Screw and Small Part Inspection?

1. Speed

Inspects each screw in under 5 seconds

Measures multiple screws at once on a single stage

2. Accuracy

Accuracy: ±10 μm

Repeatability: ±5 μm

Resolution: 1 μm

3. Simplicity

Just place the screw and press a button

No specialized operator skills needed

4. Reporting & Traceability

Every measurement logged

Reports generated automatically

Compliant with industrial audit requirements

Key Features at a Glance

Feature

Specification

Field of View

120 mm x 95 mm

Camera

20 MP Monochrome CMOS

Lens

Double Telecentric Optics

Software

Opto Precision V1

Display

21.5” Full HD Touchscreen

Illumination

Collimated Green LED

Accuracy

±10 μm

Repeatability

±5 μm

Report Generation

Real-time with summary stats

Industries That Benefit from OPTO 1200

If your industry relies on tight tolerance parts like screws, bolts, pins, and fasteners, the OPTO 1200 is for you:

Aerospace & Aviation

Automotive

Medical Device Manufacturing

Electronics & PCB Assemblers

Tool & Die Making

Defense & Heavy Engineering

From prototype analysis to full production QA, this machine fits right into your digital workflow.

FAQs — Quick Insights for Buyers and Operators

Q1: Can OPTO 1200 measure different types of screws?

A: Yes. You can create and save multiple templates for each screw type and recall them instantly.

Q2: How does it ensure accuracy for threads?

A: The double telecentric lens and edge-detection software ensure consistent and distortion-free thread measurements.

Q3: Can I use it for batch inspection?

A: Absolutely. You can place multiple screws and measure them all in one click.

Q4: Is it difficult to operate?

A: Not at all. It’s user-friendly with an intuitive interface — no metrology experience required.

Q5: Does it store past reports and results?

A: Yes. Every measurement and inspection report is saved and can be retrieved anytime.

Conclusion: Make Screw Inspection Smarter, Faster, and Reliable with OPTO 1200

In a manufacturing world driven by precision and productivity, the OPTO 1200 is your edge. It empowers your team to inspect complex parts like screws with unparalleled accuracy, zero human error, and faster cycle times.

Whether you’re inspecting 10 parts a day or 1,000, the OPTO 1200 guarantees performance, repeatability, and ease — all packed into one powerful machine.

Measure better. Deliver faster. Trust OPTO 1200.

0 notes

Text

Heat Transfer Paper Market Drivers: The Sportswear Boom and Its Influence on Heat Transfer Technologies

The heat transfer paper market has seen steady growth over the past decade, driven by technological advancements, the rising popularity of customized apparel, and expanding applications in various industries. As a crucial component in heat transfer printing, this paper allows designs to be imprinted on fabrics and other surfaces through heat and pressure, making it highly popular in textile, promotional, and craft markets.

1. Rising Demand for Customization in Apparel and Textiles

One of the leading drivers of the heat transfer paper market is the increasing consumer demand for customized and personalized clothing. With the rise of e-commerce platforms and direct-to-garment businesses, individuals and small brands are increasingly turning to heat transfer methods to produce custom t-shirts, hoodies, and accessories. This shift is not only reshaping fashion trends but also creating opportunities for innovation and mass customization at a relatively low cost.

2. Growth of the DIY and Crafting Culture

Another major boost to the heat transfer paper market is the explosion of the DIY and crafting culture, especially among hobbyists and small business owners. Platforms like Etsy and Pinterest have fueled interest in custom crafts, from tote bags to home décor items, many of which are made using heat transfer techniques. Heat transfer paper provides an affordable and accessible way for crafters to experiment with creative projects without the need for expensive printing machinery.

3. Expansion of the Sportswear and Activewear Market

The global sportswear and activewear industry is booming, and much of this apparel requires logos, names, and branding to be transferred efficiently and durably. Heat transfer paper offers a reliable method to apply such graphics with vibrant results and resistance to washing and wear. As more consumers invest in sports apparel for both athletic and casual use, manufacturers are increasingly turning to heat transfer paper to meet branding and design demands.

4. Technological Advancements in Printing Techniques

Innovation in digital printing technologies has significantly enhanced the quality and versatility of heat transfer paper. New formulations and coatings now support complex, high-resolution images, metallic finishes, and compatibility with a variety of fabrics. Furthermore, improvements in eco-friendly inks and heat press machines have made the process more sustainable and cost-effective, encouraging businesses to adopt heat transfer solutions over traditional screen printing.

5. Rise in Small and Medium Enterprises (SMEs)

The growing number of SMEs in apparel and promotional products has created a fertile ground for heat transfer paper adoption. Startups and small-scale businesses often lack the capital for bulk screen printing or embroidery equipment. Heat transfer paper, on the other hand, provides a low-barrier entry point with minimal setup costs, allowing these enterprises to produce professional-quality merchandise in small batches.

6. Environmental and Operational Benefits

Compared to traditional printing methods, heat transfer paper printing is relatively clean, safe, and eco-friendly. It generates less waste, uses water-based inks, and doesn’t involve hazardous chemicals. Additionally, the operational simplicity and low maintenance of heat transfer presses make them a preferred option for businesses aiming to streamline their production processes while adhering to environmental standards.

7. Increasing Adoption in Non-Apparel Industries

While textiles remain the dominant application, heat transfer paper is gaining traction in non-apparel sectors such as signage, ceramics, and packaging. This diversification broadens the market scope and drives innovation in heat transfer technologies suitable for rigid and unconventional surfaces.

0 notes

Text

Master Python Programming with the Best Python Training in Mohali

Are you ready to dive into one of the most powerful and versatile programming languages? Python is the language of choice for Big Data, Analytics, Machine Learning, and more, making it an essential skill for aspiring developers. At Mohali Career Point (MCP), we offer the most comprehensive and practical Python training in Mohali, Chandigarh, and Panchkula.

Why Choose Python?

Python’s simplicity and readability make it a favorite among developers and companies worldwide. Tech giants like Microsoft, Google, Facebook, and Amazon use Python extensively for various applications, including web development, data science, and automation.

What Makes MCP the Best Python Training Institute in Mohali?

Experienced Instructors: Learn from industry experts with years of real-world experience in Python and software development. Our trainers are dedicated to providing personalized attention to ensure you grasp every concept.

Hands-On Learning: Our Python course is designed to be highly practical, with real-time project development. You’ll not only learn the theory but also apply it through extensive coding exercises and projects.

Comprehensive Curriculum: We cover everything from the basics of Python to advanced topics like Django web framework and OpenCV. Whether you’re a beginner or looking to enhance your skills, our course has something for everyone.

Affordable Fees: MCP offers top-notch Python training at the most competitive rates in Mohali. Don’t miss out on the opportunity to learn Python from the best without breaking the bank.

Flexible Learning Options: We offer both online and physical classes with regular, weekend, and fast-track batches to fit your schedule.

What Will You Learn?

Our Python training covers a wide range of topics, ensuring you become proficient in Python programming:

Module 1: Introduction Learn the basics, including print statements, data types, variables, and working with IDLE.

Module 2: String Manipulation Master string operations, slicing, and typecasting, and get introduced to functions and modules.

Module 3: Data Structures Explore lists, tuples, dictionaries, and sets. Learn about comprehensions and nested list operations.

Module 4: Control Loops Understand Python program flow diagrams, loops, and conditionals with a focus on indentation and control structures.

Module 5: Functions Learn how to define and call functions, explore built-in functions, and solve problems using functions.

Module 6: Object-Oriented Programming Dive into OOP with Python, covering classes, inheritance, polymorphism, and exception handling.

Module 7: Modules and Packages Create and manage Python modules and packages, and learn to use pip for package management.

Module 8: Exception Handling Handle errors gracefully with try-except blocks and create custom exceptions.

Module 9: Variables Differentiate between global and local variables, and understand their scope.

Module 10: Advanced Concepts Explore advanced topics like map, filter, reduce, and database access using Python.

Module 11: APIs Work with APIs, understand client-server architecture, and complete a mini-project using the Google Maps API.

Module 12: Introduction to Data Science Get introduced to data science with Pandas and Numpy, and work on analyzing real-world datasets.

Module 13: Introduction to Machine Learning Learn the basics of machine learning using Scikit-Learn and complete a project on stock market prediction.

Start Your Python Journey Today!

If you’re searching for the best Python coaching institute in Mohali, MCP is your answer. Our expert faculty, comprehensive curriculum, and hands-on approach will give you the skills you need to excel in the tech industry.

1 note

·

View note

Text

Future Trends in Manufacturing Sector ICT Market: Predictions for Industry Evolution and Innovation

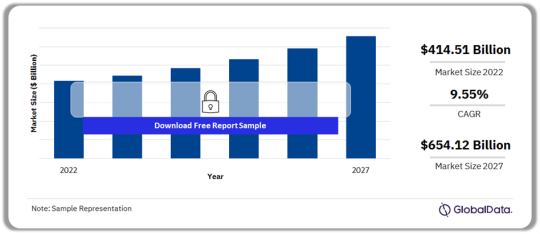

The manufacturing sector ICT market is poised for significant evolution and innovation driven by emerging technologies and shifting industry dynamics.

Buy the Full Report for More Insights into the Manufacturing Sector ICT Market Forecast

Download a Free Report Sample

Here are some predictions for future trends in the manufacturing sector ICT market:

AI-Powered Manufacturing: Artificial intelligence (AI) will play a central role in transforming manufacturing operations, with predictive analytics, machine learning, and cognitive automation enabling predictive maintenance, quality control, and demand forecasting. AI-powered systems will optimize production processes, reduce downtime, and improve overall efficiency.

Digital Twins and Simulation: The adoption of digital twins will become more widespread, allowing manufacturers to create virtual replicas of physical assets and processes. Digital twins will enable real-time simulation, optimization, and analysis of manufacturing operations, leading to better decision-making, faster time-to-market, and improved product quality.

Edge Computing for Real-Time Insights: Edge computing will gain prominence in manufacturing environments, enabling data processing and analytics to be performed closer to the point of data generation. Edge computing architectures will support real-time monitoring, analysis, and control of manufacturing processes, enhancing agility and responsiveness.

5G Connectivity for Smart Factories: The rollout of 5G networks will enable high-speed, low-latency communication between devices and systems in smart factories. 5G connectivity will support a wide range of IoT devices, robots, and autonomous systems, enabling real-time data exchange, remote monitoring, and control of manufacturing equipment.

Cyber-Physical Systems Integration: Cyber-physical systems (CPS) integration will enable seamless interoperability between digital and physical components in manufacturing environments. CPS will enable autonomous production processes, self-optimizing systems, and adaptive manufacturing capabilities, driving efficiency and flexibility.

Advanced Robotics and Automation: Robotics and automation technologies will continue to evolve, with advancements in robotics capabilities, collaborative robots (cobots), and autonomous guided vehicles (AGVs). Robotics and automation will enable flexible, scalable, and agile manufacturing operations, improving productivity and reducing manual labor.

Blockchain for Supply Chain Transparency: Blockchain technology will be increasingly used to enhance supply chain transparency, traceability, and trustworthiness. Blockchain-enabled platforms will provide secure, immutable records of transactions, ensuring authenticity and provenance of products throughout the supply chain.

Augmented Reality (AR) for Training and Maintenance: Augmented reality (AR) technologies will be integrated into manufacturing processes for training, maintenance, and remote assistance. AR-enabled tools will provide interactive, hands-on training experiences, facilitate troubleshooting, and improve productivity on the shop floor.

Sustainable and Green Manufacturing Practices: Manufacturers will prioritize sustainability and environmental stewardship, leveraging ICT solutions to reduce energy consumption, minimize waste, and optimize resource usage. Sustainable manufacturing practices will become integral to corporate social responsibility (CSR) initiatives and brand reputation.

Personalized and On-Demand Manufacturing: Advances in ICT will enable personalized and on-demand manufacturing models, allowing manufacturers to produce customized products in small batch sizes at scale. ICT solutions such as 3D printing, digital design tools, and agile manufacturing processes will support flexible and adaptive production capabilities.

In summary, the future of the manufacturing sector ICT market will be characterized by AI-powered manufacturing, digital twins, edge computing, 5G connectivity, cyber-physical systems integration, advanced robotics, blockchain for supply chain transparency, AR for training and maintenance, sustainable manufacturing practices, and personalized manufacturing models. These trends will drive innovation, efficiency, and competitiveness in the manufacturing industry, paving the way for the factories of the future.

0 notes

Text

Unveiling the Magic of Vibratory Tumblers: Polishing Precision Redefined

In the world of metalworking, jewelry crafting, and various industrial processes, achieving a flawless finish is often the ultimate goal. Enter the vibratory tumbler, a remarkable innovation that has revolutionized the art of polishing and deburring. This article delves into the intriguing world of vibratory tumblers, exploring their mechanics, applications, and the magic they bring to surface refinement.

The Mechanics Behind Vibratory Tumblers

At its core, a vibratory tumbler is a machine designed to enhance the surface finish of various materials. Whether it's a batch of gemstones, metal components, or even 3D-printed parts, the vibratory tumbler employs a simple yet effective principle. The machine consists of a bowl or chamber that holds the objects to be polished and a motorized mechanism that imparts vibrations to the bowl.

As the tumbler vibrates, a carefully selected abrasive media interacts with the objects, creating friction and agitation. This process gradually smoothens rough edges, removes imperfections, and imparts a remarkable shine to the surfaces. The vibratory action is akin to nature's own process of erosion, albeit harnessed and expedited for human precision.

Applications in Various Industries

Vibratory tumblers find homes in an array of industries. Jewelers utilize them to give gemstones an exquisite luster, while metalworkers rely on them to deburr and refine intricate metal components. Manufacturers benefit from vibratory tumblers in finishing 3D-printed parts, achieving a professional appearance. Firearms enthusiasts even use them to polish gun casings and reloading components.

What sets vibratory tumblers apart is their versatility. By selecting the right abrasive media and adjusting the intensity and duration of vibrations, operators can achieve specific results, from mirror-like finishes to controlled edge rounding. This adaptability makes vibratory tumblers indispensable tools for industries where precision and aesthetics go hand in hand.

The Magic of Efficiency and Consistency

Vibratory tumblers are not only about enhancing aesthetics but also improving efficiency. Compared to traditional hand-polishing methods, these machines can process large quantities of items simultaneously, ensuring consistent results across the batch. This translates to reduced labor costs, quicker turnaround times, and a remarkable improvement in overall productivity.

Moreover, vibratory tumblers eliminate the risk of human error. With precise control over variables such as vibration intensity and media selection, manufacturers can consistently reproduce desired outcomes. This reliability has earned vibratory tumblers a prime spot in quality control processes, ensuring that each product leaving the production line meets exacting standards.

Conclusion

In a world where precision and aesthetics are paramount, vibratory tumblers stand as a testament to human ingenuity. These unassuming machines have revolutionized surface refinement, making the arduous tasks of polishing and deburring an efficient, consistent, and magical process. Whether in a jeweler's workshop, a metal foundry, or a manufacturing facility, the vibratory tumbler continues to redefine excellence, one polished surface at a time.

0 notes

Link

Krishna Engg. & MFG. PVT. LTD. Is expert leading manufacturer. Side & Back Stopper is provided for margin setting for large Labels / Cartons / Pouches, Extension Platform support with side stoppers provided. Hand operated batch printing machine, batch coding machine, printing equipment, printing machine, batch printing machine, we are also Manufacturing Printing Machine, Batch Coding Machine, Rewinding Machine, Industrial Roller, etc…

#Hand operated batch printing machine#batch coding machine#printing equipment#printing machine#batch printing machine#Machinery#Batch Printing Machine Manufacturer#Printing machine exporter#Printing Machine Supplier#Manual Printing Machine

0 notes

Link

We Are Exporter, Manufacturer & Supplier Hand Operated Batch Printing Machine Models, Manual Batch Printing Machine, Semi Automatic Batch Printing Machine, Automatic Batch Printing Machine, Batch Coding Machine. Hand Operated and Semi Automatic Batch Printing/Coding Machines are working on the same principal of tradle machine conventionally used by all the printers. While in Hand Operated Batch Printing/Coding Machine in addition of feeding and discharging the Labels/Cartons/Bags by hand, the stroke of the machine is also operated by hand.

#Hand Operated Batch Printing Machine#Semi Automatic Batch Printing Machine#Batch Printing Machine#Batch Printing Machine Manufacturer#Batch Printing Machines#Batch Coding Machine#Batch Coding Machines#Batch Coding Machine Manufacturer#Manual Batch Printing Machine#Automatic Batch Printing Machine#Automatic Batch Coding Machine

0 notes

Link

Hand Operated Batch Printing Machine manufacturer, exporter, and supplier, Hand Operated Batch Printing Machine specialized designed for industries. Hand Operated Batch Printing Machine manufacturer high-quality equipment for printing on labels, Pouches etc. With rich industry experience and knowledge, we are providing an excellent quality range of Hand Operated Batch Printing Machine. Hand Operated and Semi Automatic Batch Printing/Coding Machines are working on the same principal of trade machine conventionally used by all the printers.

#Hand Operated Batch Printing Machine#Batch Printing Machine#Batch Printing Machine Manufacturer#Batch Coding Machine#Batch Coding Machine Manufacturer#Code Printer Machine#Batch Printing Machines#Batch Coding Machines

0 notes

Text

Discover How 3D Print Services and Cheap 3D Printer India Solutions Are Transforming Innovation

In recent years, 3D printing technology has emerged as a powerful tool across industries—from prototyping and manufacturing to healthcare and education. Businesses and individuals alike are reaping the benefits of rapid, cost-effective production using modern 3D printers. With increasing accessibility, more Indians are turning to 3D print services and exploring options for a cheap 3D printer in India to bring their ideas to life.

Why 3D Printing Is Gaining Momentum

3D printing, also known as additive manufacturing, creates physical objects by layering material based on a digital model. This process dramatically reduces waste, speeds up prototyping, and allows for the customization of products that traditional manufacturing struggles to offer.

Designers, architects, engineers, hobbyists, and students are now using 3D printing for projects ranging from miniatures and machine parts to architectural models and medical implants. The rising interest has spurred the growth of reliable and affordable 3D print services and a market boom for cheap 3D printer India options.

What Are 3D Print Services?

3D print services allow you to print a design without owning a 3D printer yourself. You simply upload your CAD file to an online portal or visit a local 3D printing center, choose your preferred material, and let experts do the rest. These services are ideal for those who need professional prints occasionally or want high-quality output without investing in expensive machines.

In India, the demand for professional 3D printing has surged across metro cities like Bangalore, Delhi, Mumbai, and Hyderabad. Companies offer services like rapid prototyping, industrial modeling, product design, and even small-batch production. Whether you're a student working on a science fair project or a startup developing a new prototype, 3D print services provide flexible, on-demand solutions.

Exploring the Market for a Cheap 3D Printer in India

While outsourcing printing to professional services is convenient, many hobbyists and startups prefer owning a machine for hands-on experience and long-term savings. The good news is that the Indian market offers a wide range of options for those seeking a cheap 3D printer in India without compromising on performance.

Entry-level FDM (Fused Deposition Modeling) printers are now available at affordable prices, starting as low as ₹15,000 to ₹30,000. Brands like Creality, Anycubic, Wanhao, and Indian-made Pramaan 3D have released budget-friendly models that cater to both beginners and advanced users.

These machines support common filament types like PLA, ABS, and PETG, and some even come with open-source firmware for customization. With online tutorials and active user communities, it’s easier than ever to set up and operate a cheap 3D printer in India from your home or workshop.

Benefits of Using 3D Print Services and Owning a Cheap 3D Printer

Both 3D print services and affordable personal printers offer distinct benefits, depending on your needs:

Advantages of 3D Print Services:

Professional Quality: Get access to high-resolution industrial-grade printers.

Variety of Materials: Choose from advanced resins, metals, and composites.

No Maintenance Hassle: Avoid the setup, calibration, and upkeep involved in running your own printer.

Expert Guidance: Collaborate with technicians who can help optimize your design for the best results.

Advantages of Cheap 3D Printers in India:

Affordability: Entry-level printers are budget-friendly and easily available online and offline.

Learning Opportunity: Great for students and makers to understand the nuances of 3D modeling and printing.

Creative Control: Make quick iterations and modifications in real time without relying on a third party.

Business Potential: Entrepreneurs can start small-scale manufacturing or offer local 3D print services in their area.

Who Can Benefit from 3D Printing?

The applications of 3D printing extend far beyond engineering and manufacturing. Here’s a look at some key users:

Students and Educators: Ideal for STEM education, science models, and project-based learning.

Architects: Use 3D printing for scale models, elevation designs, and visual presentations.

Healthcare Professionals: Print prosthetics, surgical tools, and anatomical models.

Artists and Designers: Bring creative ideas to life with customized jewelry, home decor, and wearable tech.

Entrepreneurs: Launch product-based businesses with minimal initial investment using a cheap 3D printer India setup.

Final Thoughts: Embrace the Future with 3D Printing

The 3D printing landscape in India is rapidly evolving. As awareness grows, both 3D print services and affordable home-use machines are making innovation more accessible than ever. Whether you want to prototype a new invention, create personalized items, or enter the world of digital manufacturing, now is the perfect time to explore your options.

Investing in a cheap 3D printer in India or partnering with a local 3D print service can unlock endless possibilities for your creativity or business. As technology continues to advance, those who adopt 3D printing today will lead the way in shaping the products and solutions of tomorrow.

0 notes

Text

Selling Weapons to the Foot

~ Ever since she moved to NewYork Karai has known about you. You were one of the Foot Clans top supporters and suppliers after all. It helped that her Father often talked about you (She thinks he has a crush but stubborn old him won't ever admit it)

~ A well trained martial artist who's studied different styles and techniques your arsenal matches your fighting ability, which pleases Saki greatly. Anything Karai or her father could ask for your able to provide and more. You prefer to stick to your usual delivery of weapons but if Shredder has an odd request like the occasional batch of rare chemicals, extra mutagen, or lab equipment your able to get whatever he needs.

~ The operation you run is smooth something everyone in the crime world notices and appreciates. You don't do drugs, you don't do woman, and you stick to what you know. Your labs are top quality with only the best tools and equipment and your sanitation of raw matierals and the finsihed product is key. Anything that needs to be stolen is done quickly and efficiently and everything else you either buy or manufacture in your own lab.

~ New toys and prototypes for the Shredder are a given. He's always looking for an edge on those mutant turtles and your always looking for a large profit. New weapons are carefully labeled and put in cases with the instructions on how to build and use them inside. On every case with high end products there's a finger print lock so only he or Karai can access them and only they can add more people to open the case. You make it very clear to Oruku when something is hazardous so any damage that comes to Shredders men is not your fault. You may make the weapons but you take no responsibility for what's done with them.

~ Oruku is aware he's not the only buyer and he won't lie that does make him jealous. The Purple Dragons as stupid as they are do grunt work in exchange for cheap upgrades, they do errands and jobs you don't want or need traced back to you. Hun or Xever are also always willing to buy your more dangerous weapons that no one else wants so it's a good trade off. Anton Zeck has stolen you a great deal of tech and chemicals over the years for prototype perks, the theif loves seeing what you come up with and how much better your scientists can make his suit. Don Vizioso and the Fulci Twins almost always need something and almost always call you first. And then there's Ivan Steranko. He also deals weapons but he understands partnership better than most in your line of business, you two have an agreement. Many of your weapons that are made special ordered come from him. Ivan keeps them in his personal vault saying he likes your artistry and how well made every weapon is. You have an understanding of some sort with every mob, gang, and crooked cooperation in the city.

~ Many times Oruku Saki has tried to merge your companies and make your weapon line exclusive to the Foot Clan. Every time you've gently had to reject him. Him and his daughter fancy you, you think. And you'd be lying if you said you didn't fancy them. As Shredder buys more territory and expands his reach in New York showing off his wealth and power but also his strategic mind you begin to rethink his offer.

~ Shredder is not a forgiving man but he's never had to forgive you, you always get the job done. He is also not a forgetful one. He values your good work and often pays you much more than the agreed upon price. The only friction in your relationship comes from not just working for him but he can't afford to lose you as a supplier so he listens to your demands and requests. Your one of the only ones he'll go to for advice abd your opinion means a great deal to the samurai.

~ Everything is top of the line and crafted carefully. Some of the weapons are made with machines but only the best of the best humans are on your team. Every blade is hand sharpened, every gun practiced and tested before going into a case, and every chemical or computer part is carefully monitored and scanned for glitches before being shipped away. Your brand doesn't do mistakes. It's known for nothing less than perfection, just as you are.

~ Your the head of your operation and you built up from nothing. Everyone on your ever expanding team answers to you and all the trades are done with your watchful eye. If anyone shorts you, your known for your quality of your weapons but also the contingences placed inside them. Everyone smart knows what happens when you cross (Y/N).

~ You are always early and respectful when doing handoffs and you always leave the Foot Clan with a little extra something. Shredder is more than thankful for your shipments. You seem to know what Karai likes by now and what he always needs more of even if he didn't order it. Shredder is pleased with you and your results and is impressed how your always able to stay a step ahead of the turtles and Krang. You've known Saki for little over a year now and Karai notices the way her father looks at you and the tenderness in his actions as he hands over the money. The way his hand gently touches the back of yours. As this business relationship goes on she wonders if either of you will make a move and make things less professional.

~ Your operation is massive and always has multiple backups in circulation. Saki is aware of your many bases and when weapons are in development he often has soldiers nearby just in case something happens. He wants his best supplier safe after all.

~ Every lab is cleaned professionally before and after each shift, and everything is monitored very closely by someone on cite. There are only heat sensor cameras in the lab to keep everyone's identities a secret and you only use scinetists, mechanics, engineers, and security that want to be there. No one is held captive and they can stop at any time with certain stipulations. Your also very clear you leave no loose ends, do your job right or make up for your mistakes and make up for them fast. Everyone knows what happens if the person isn't able to do that. Your like Shredder in that way.

~ For all intensive purposes you've never been caught on paper, the cops have never captured evidence of your facilities, and your labs are pratically a myth. You've been lucky to avoid the turtles abd Krang so far. Your very good at hiding your tracks and your known for being through with any loose ends.

~ Although you don't sell exclusively to the Foot Clan they do get a lot of perks with your business. Part of this is from the extra money Shedder gives you each shipment but part of it is from a mutual understanding and a want to get closer to the head of the Foot. Karai gets to test out a majority of your prototype weapons and has first pick of what she wants for the next shipment. The Shredder is also the first to know about anything your building or stealing that may interest him. Oruku rewards your loyalty with money but also secrets and benefits of his own. He invites you to high society events to network and although you wouldn't call them dates you've definetly grown closer to the leader through them. You know of Teng Shen and her passing but your patient, if Oruku wants to make a move you'll let him process his grief before starting a relationship with you.

~ If Shredder and Karai can't pick up an order you meet with Shredders mutants. You got used to them a long time ago so there's never any surprises and you've even given them specially made upgrades to help them fight better with their mutations. You know what happened to mutate them and you know how it all works, you never ask any questions because you have all the answers you need. Thats something they all admire about you, you don't ask many questions.

~ Xever before his mutation used to be a constant buyer so you two have a fun work relationship. You like to gossip as weapons are being loaded and he always has a tip for your next big buy or steal. He also informs you of Hun and how the Purple dragons are doing. He does however often ask if you and Shredder are a thing. Appretally him and Rahzor have a bet and he want the dog to pay up. You never directly answer but Xever has a feeling he'll be making a lot of money soon.

~ When he became Mr. X and started his little underground sewer games you were a known gambler at his games. It was a way to network and catch up with everyone but also a fun source of income. Sadly for Xever you always made more than what you spent because you were that good.

~ DogPound and eventually Rahzor has known you for a long time. When he used to be Bradford he would often be there with Shredder when dealings were going on and he'd asked his master more than once why they paid so much for your "junk". You always kept calm about it but it was obvious you didn't like each other something Saki found highly amusing. Unlike Xever, Rahzor is all business and doesn't engage in pleasantries outside of work. He's always been the serious efficient type so you don't push him and get your sales done quickly when he's in charge. He always makes a comment about how Shredder never shuts up about you so at least you know Saki talks about you when your not around.

~ TigerClaw is very professional during dealings but the cat is not immune to your games. Although TigerClaw is strictly under servitude to Shredder the cat does hold a deep respect for you and how you run your business. You have a moral code it's just not what most people would call "ethical". He's surprised you and Shredder have not become an item yet but doesn't pry. He does however often mention that Shredder speaks highly of you and your work. The cat is smug if this gets you flustered and always reports his interactions to his master.

~ BeepBop and RockSteady or Anton and Ivan now work under Shredder and had become mutants. Neither of them were allowed to do deals alone but whenever you saw them it was nice to talk with old friends. Ivan still had special ordered weapons under the table and if Anton ever had problems with his suit he came to you rather than Shredder. Anton however never shut up when you were installing upgrades and asked when you and Shredder were getting married.

~ Eventually after a year or more of pining you accept Shredders offer and make your company exclusive to his people. He now owned everyone you used to sell to anyways so it seemed like a sound business decision. After sighing the paper work and handing over a contract Saki smiled before taking off his kubuto asking if you'd like to go on a date together sometime, a real date not a business transaction. You accept.

...

Like my work? Consider a commission or buy me a coffee. Link:

#2012 tmnt#2012 tmnt shredder x reader#shredder x reader#2012 shredder#karai#2012 tmnt karai#2012 tmnt karai x reader#karai x reader#platonic karai#platonic tmnt#tmnt x reader#2012 tmnt x reader#2012 tmnt tigerclaw#tigerclaw#2012 tmnt xever#xever#2012 tmnt fishface#fishface#2012 tmnt bradford#bradford#2012 tmnt rahzor#rahzor#2012 tmnt beepbop#beepbop#2012 tmnt anton zeck#2012 tmnt ivan#ivan#2012 tmnt rocksteady#rocksteady#2012 tmnt hun

383 notes

·

View notes

Text

Puzzles Made by Laser Cutting Are Far Beyond Our Imagination

Do you still remember the feeling when you play puzzles for the first time? As each piece clicks perfectly into place, it is a little win, like a little pat on the back. You are feeling weirdly soothing, therapeutic.

Toys are not only for children. In many nursing homes, jigsaw puzzles are often a part of the leisure for the elderly. Similarly, in some geriatric rehabilitation hospitals, jigsaw puzzles are also indispensable for the patients to exercise their hands-on ability.

In fact, in Europe, puzzles are more popular in the adult world, and even children's favorite Legos are widely discussed in the adult world.

We would like to share with you some interesting jigsaw puzzles and hope can give you some inspirations:

An actual trip to the lake or woods—not to mention outer space—might not be feasible right now, but these model kits by the Portland-based shop Houha Designs provide a small escape. All you need is a bottle of glue to fix each laser-cut piece to the next to create a fishing boat, fire tower lookout, or circular spaceship.

The design company Areaware released nearly 30 tasty main courses, snacks, and so on. We are used to seeing how food disappears in front of us, but this time, you can restore and present your "food"little by little. You might want to pick up a few if you are a super eater.

If you're looking for more modern puzzles to keep you busy during quarantine, you have to check out this.

Nervous System released a new series of spiral puzzles. Instead of working from the outside in, or in sections, the puzzles are meant to be pieced together in a swooping spiral in the shape of an ammonite fossil or nautilus shell. The puzzles are made from laser cut wood and contain a variety of whimsy pieces like octopi and seahorses.

Have you ever seen an acrylic puzzle? This puzzle is like shattered glass but it can be reassembled into a single sheet. Yelldesign turns a mistake into a delicate art piece. "The Accident" is comprised of 215 jagged and cracked pieces resembling a broken window but as per the designer, you don't have to worry about getting cut or scratched by these pointed edges. These acrylic puzzles booms in sales as people around the world are looking for indoor recreations during the quarantine.

Due to the small batch and high degree of complexity, these kinds of puzzles are often processed by laser cutting technology. Once you have a laser cutting machine, you don’t need to be a graphic designer to make a puzzle unique to you. Conceiving a whimsy pattern of pieces is all you need to do to make your puzzles original and unique.

A laser machine can not only enable you to cut out puzzles but also engrave them to enrich the design and meet the needs of personalized customization. It can pattern your puzzles with delicate styles and turn your incomparable vector designs into products with no limitation. Moreover, it gives small SMEs (small and medium-sized enterprises) the opportunities to take orders small as one single unit customized produced, large as thousands of productions in batches, all within affordable investing prices.

Who are we:

Mimowork is a results-oriented corporation bringing 20-year deep operational expertise to offer laser processing and production solutions to SMEs (small and medium-sized enterprises) in and around clothing, auto, ad space.

Our rich experience of laser solutions deeply rooted in the advertisement, automotive & aviation, fashion & apparel, digital printing, and filter cloth industry allows us to accelerate your business from strategy to day-to-day execution.

We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator. Please contact us: Linkedin homepage and Facebook homepage or [email protected]

#jigsaw#puzzle#toy#lasercutter#developers & startups#business#manufacturing#diy woodworking#woodcraft#woodart#wooddesign#acrylic#custom

1 note

·

View note